Why Fuel Pumps Fail — and How to Extend Their Life

Your Fuel Pump’s Job—and Why Failure Happens

Your vehicle’s fuel pump plays a simple but critical role: moving fuel from the tank to the engine at the correct pressure. Over time, though, the pump and its supporting components naturally wear down. The underlying cause might be a failing electric motor, a weak sensor, a stuck valve, a compromised relay, or another aging electrical part.

No matter the root issue, the end result is the same: a fuel pump that can no longer reliably deliver fuel, leaving you stranded instead of traveling the roads around Linn and central Missouri.

And because fuel pump assemblies are integrated units, replacing only the failed part is often a temporary fix. If one piece of the system has reached the end of its life, the rest usually isn’t far behind. That’s why technicians recommend replacing the entire pump assembly to avoid repeated labor costs and prevent additional breakdowns.

Why Fuel Pump Replacement Is Labor Intensive

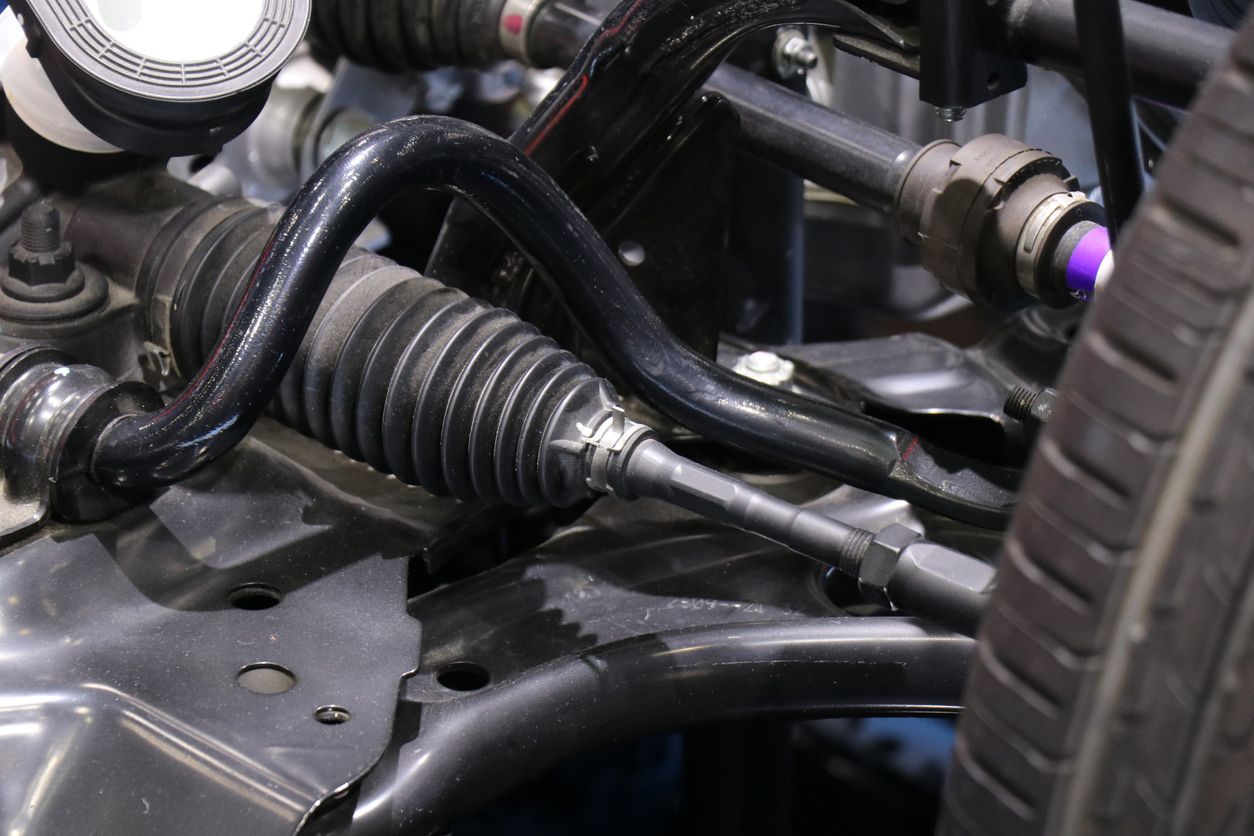

On most modern vehicles, the fuel pump is located inside the fuel tank. Reaching it isn’t as simple as opening the hood—many cars, trucks and SUVs require complete tank removal.

This process often includes:

- Removing heat shields and tank-retaining straps

- Disconnecting EVAP lines, fuel lines, and electrical connections

- Safely draining and handling gasoline

- Lowering and reinstalling the tank without damaging components

Because of this complexity, fuel-pump replacement is a job where professional expertise and proper safety practices matter.

Some vehicles also use external fuel filters that should be replaced at the same time to prevent debris from reaching the brand-new pump. In cases where a fuel tank is corroded or built with specific manufacturer materials, fuel-tank replacement may also be recommended.

Two Smart Ways to Help Your Fuel Pump Last Longer

While no fuel pump lasts forever, you can take simple steps to extend its life.

1. Keep Contaminants Out of the Fuel Tank

Fuel contamination is one of the fastest ways to shorten pump life. It can come from poor-quality fuel or from sediment that accumulates in older tanks.

To protect your pump:

- Fill up at reputable stations in and around the Linn area

- Inspect older tanks for rust or sediment buildup

- Clean or replace compromised tanks when necessary

A clean fuel environment reduces strain on the pump and protects the rest of the fuel-delivery system.

2. Don’t Let the Tank Run Too Low

Your fuel pump is cooled and lubricated by the fuel around it. When your tank drops below a quarter full:

- The pump works harder to draw fuel

- There’s less liquid to cool the system

- Heat builds up, causing premature wear

Keeping at least a quarter tank is an easy habit that significantly extends pump life.

What You Can Expect From DJ’s Repair Service

When your fuel pump finally needs replacement, DJ’s Repair Service ensures the job is done correctly, safely, and with quality components. Our technicians:

- Install manufacturer-grade or better replacement assemblies

- Confirm compatibility with your fuel type

- Use ethanol-rated pumps for FlexFuel vehicles (E85 systems require components that resist high-alcohol corrosion)

- Inspect related components to ensure long-term reliability

We focus on giving you a repair that lasts, not one that sends you back into the shop with recurring issues.

Final Takeaway

Fuel-pump replacement is a major service that affects the reliability and safety of your vehicle. With proper maintenance habits and trusted local technicians, you can maximize your pump’s lifespan and ensure dependable performance for years to come.

If you're noticing hard starts, sputtering, stalling, or reduced fuel efficiency, schedule an inspection with DJ’s Repair Service in Linn, MO before the issue escalates.

Recent Posts